Welcome to the C&C 99 Class Association

The C&C 99 is an American sailboat that was designed by Tim Jackett and entered production in 2002.

“I was dubious about the 99’s ability to handle our conditions (Australia) so had a re-engineered forestay tang and a custom designed anchor roller to reinforce the the tang. The sails have been cut for offshore conditions, light but strong and can be reduced at a moments notice. I use my boat whenever I get the opportunity all year round and can stay aboard for up to a week before I need to refill water tanks. I have a 100 litre bladder behind the sullage tank. I manage to be able to sail with a 5.2M paddle ski inside the rails without sheets getting caught.

The boat is a great all rounder and a lot more fun than the S&S’s. I have certainly given it a pounding and it has stood up well so far. Without any crew means I have to reduce sail earlier in the piece but maintains a good speed in all conditions. I plan to go a little further when the opportunity arises.“

Cruising World’s Best Performance Cruiser for 2002

via. Cruising World

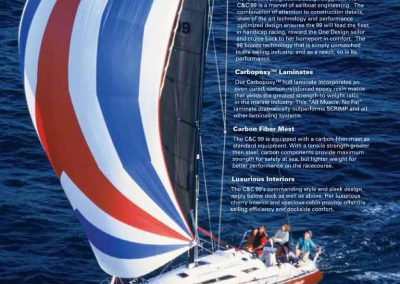

With its new C&C 99, Fairport Yachts is obviously targeting sailors interested in a raceboat that can also be cruised. But even geezers like me, with a penchant for performance gunkholing rather than regattas, will see the merit in this seagoing roadster. Her powerful sail plan, stiff demeanor, and safe side decks merge with a modest-sized cabin house cleanly perched on a light but stiff hull with a long waterline and a fair ration of form stability.

The result is an action-oriented 32-footer that’s all sailboat, rather than a surrogate beach house, and an excellent value in performance and structure. The C&C 99 is built with technology that’s a notch above standard industry practice. I sailed the boat last fall with Tim Jackett, her designer, and it was instantly clear to me how his hands-on involvement with the project turned a good idea into a great sailboat.

Jackett also is the chief operating officer for Fairport Yachts, builder of C&Cs and Tartans. In addition to playing a key role in the corporate decisions, he remains the company’s lead designer. Judging from this innovative racer/ cruiser, wearing both hats hasn’t diminished his creativity.

When Jackett set out to design a new boat that would sport the familiar C&C logo, he didn’t stop with a set of lines drawings and a table of offsets. His participation continued through the building phase and even long after the boat left the factory. Along the way, he remained intimate with the details. He sailed the new sloop all summer with his kids; then, in January, he took her to Key West, where he won his class in one of sailing’s toughest week-long regattas. To me, however, the Key West success is overshadowed by an even bigger success: the value this boat holds for cruisers who like one that’s a pure pleasure to sail. That’s why I, along with the other CW Boat of the Year judges, voted the 99 the Best Performance Cruiser for 2002.

A Closer Look

My overall impression of the C&C 99 is summed up in one word: “Balance” describes how the boat looks and sails as well as how design decisions were blended to create a practical racer/cruiser. This attribute enables the C&C 99 to stand tall in a forest of production peers.

The 99 isn’t an update of traditional C&C boats. Still, she remains faithful to a design approach that for decades has kept the C&C logo visible on the waterfront. For example, as I stepped into the cockpit, I quickly noticed that lines lead cleanly from blocks and cars to winches, the helmsman had several seating options, and a crew could trim the genoa without elbowing the jaw of the crewmember trimming the main. Even more captivating was the ease with which the balanced sail plan could be handled. Under main alone, the boat tacked cleanly, which is handy when sailing in crowded harbors.

Under sail, the boat excelled—not in a quirky raceboat context but in an easy-to-handle, well-behaved, maneuverable fashion. Her large rudder helped balance the boat nicely when beating to windward with just the slightest amount of weather helm, a favorable trait. The Edson steering system was strongly installed, and the helm was butter smooth. Tacking and jibing are easy singlehanded endeavors.

Initially, I was concerned about the wedge shape of this racer/cruiser, whose beam is carried well aft. But a closer look revealed how fore-and-aft changes in the flare and volume helped prevent the broaches caused by rudder ventilation seen on many other boats her size. Even when we were overpowered and lacked the rail meat to keep the boat flat, she still resisted broaching. While I followed the C&C 99 in a runabout, watching her cut through the water on different points of sail, she was reluctant to root her bow and raise her stern, which no doubt helps keep her rudder in play.

The roller-furling jib was a snap to handle. And although there’s about 300 square feet of mainsail, it’s set up with single-line slab reefing led aft and with all the “big-boat” sailhandling controls (vang, outhaul, traveler, and a double-sided mainsheet with fine and gross tails). Owners who sail shorthanded might want to add a Dutchman system or lazy jacks to simplify setting and dousing the big mainsail.

Construction Quality

Tipping the scales at just 9,265 pounds, the 99’s a boat racing sailors will find fairly light; to cruisers, she’s absolutely a flyweight. However, she’s built to high standards. A friend of mine, Paul Miller, is a naval-architecture professor at the U.S. Naval Academy and a structures specialist with a Ph.D. He once said, “The single best move a composite boatbuilder can make is switching to epoxy laminating resin,” which is what C&C has done for the hull of this boat. Incidentally, some recent laminate destruction tests performed in his U.S.N.A. labs revealed that ATC Core-Cell and epoxy resin were a very compatible, structurally sound duo.

The hull is a sandwich structure that gets laid up with E-glass fabric; Kevlar is used in high-load areas. The fabric is wetted out with epoxy resin using a mechanical impregnator to ensure complete saturation. Combined with vacuum bagging, this technique improves resin-to-fiber ratios when compared with traditional hand-layup techniques. Next, the hull is baked in an oven for eight hours to post-cure the epoxy resin. The builder gradually ramps up the temperature, increasing molecular cross-linking, thereby strengthening and stiffening the composite structure. The resulting hull element has superior mechanical properties and a low void content. ATC Core-Cell foam is used below the waterline, and Baltec AL-600 is the core material laminated into the topsides and deck. A Mars Metal bulbed keel is attached with stainless-steel keel bolts.

Her canoe-shaped underbody, fin and bulb keel, and deep spade rudder are far from the cruiser’s traditional model, so this boat may not fit every cruiser’s needs. Case in point: Load-carrying capability for extended cruising is sparse. Tankage is 40 gallons of water, 20 gallons of fuel, and 20 gallons of effluent. Then again, this is a 32-footer. There’s also the negative impact of weight on performance and the limitations of space for storage.

Obviously, this boat isn’t a deep-bilged, high-wetted-surface load hauler. She’s fleet and meant to be cruised without all the stuff you horde in the garage. Still, you won’t be roughing it. There’s a functional galley with two-burner LPG stove, and provision is made for an optional microwave oven. The two saloon settees work well as underway berths once lee cloths have been rigged, and berths forward and aft are good for sleeping in port. She sleeps six, is comfortable for four, and will seem luxurious to a couple headed off for a weekend or for a few weeks of adventure. She owns an ISO Category A offshore approval and has a limit of positive stability of about 122 degrees.

One area of concern for me was the outward cant of the pushpit at the stern. From the dock, it seemed like it could cause a crewmember to lean away from the deck on which he or she stood in order to grasp the stainless-steel tubing. Under sail, I intentionally moved about the cockpit to calculate the risk of this outward bend of the rail. Under normal sailing situations, it didn’t seem to be a problem, and the use of the swim-step transom appeared to be a workable arrangement.

The stainless-steel handrails, stanchions, and other hardware were fastened with through-bolts or were tapped into stainless-steel bar stock that follows the curve of the toerail. The metal toerail was fastened with stainless-steel machine screws tapped into the bar stock. All hardware was nicely bedded and securely fastened. There were cleats fore and aft (which you don’t always see on racer/cruisers of this size), but an anchor roller is on the options list.

Systems

The Volvo MD2020 is a 19-horsepower diesel with sail drive that pushes the vessel through a calm at just over 6 knots, runs as smoothly as a clock, and sips about two-thirds of a gallon per hour. The engine fits snugly beneath the companionway ladder. Like powerboat outdrives and other sail drives, these units bring with them the potential of galvanic corrosion and seal failure. Most engineers will advise you to religiously maintain the sacrificial zincs and regularly check nearby through-hulls and other submerged metals.

Fairport Yachts has made a noticeable effort to meet guidelines set by the American Boat & Yacht Council. The wiring is well done, and systems for fuel and plumbing use top-quality hardware.

Perhaps the best news of all is that with a base price of $114,500 (not including sails), this dual-purpose sloop should attract considerable attention, and once two or more sister ships are cruising along together, there’s no doubt it will be called a race.

C&C 99 Photos

Contributing Photographers

Trevor Lowthers

(https://tlow.smugmug.com)

Tim Wilkes Photography

(http://www.timwilkes.com)